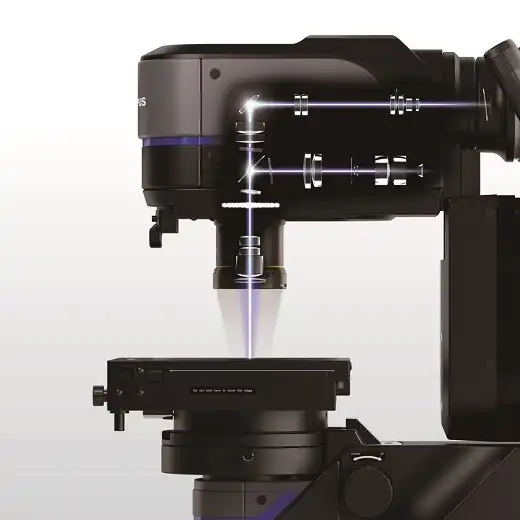

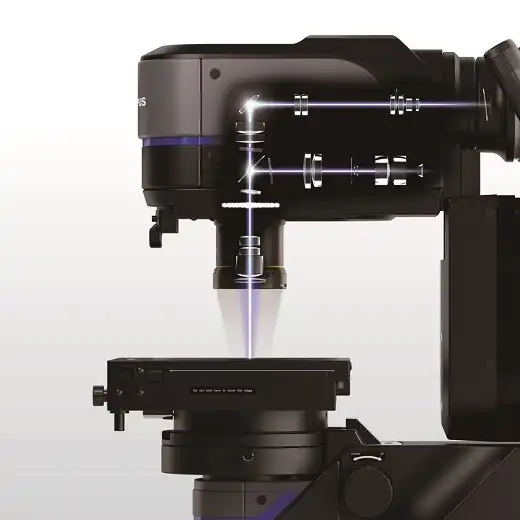

DSX1000 Digital Microscope

Powerful Analysis, Dynamic Imaging.

The DSX1000 digital microscope combines ease of use with advanced features to streamline your inspection workflow.

- Large selection of lenses that are easy to change

- Switch between 6 different observation methods by pushing a button

- Fast macro to micro viewing

- Accurate measurements with a telecentric optical system

- Advanced measurements are fast and easy to obtain

DSX1000 Digital Microscope Models

Choose the DSX1000 digital microscope that best suits your needs.

Entry Model

|

Tilt Model

|

High-Resolution Model

|

High-End Model

|

|

Easy to Use with Basic

Functionality

Standard zoom head, offering

5 observation methods.

|

See Your Sample from

Many Angles

Offers all the features of the

Entry model and adds a tilting

frame, motorized XY stage,

and console.

|

High-Resolution Images for

Advanced Analysis

Universal zoom head adds

differential interference

contrast imaging, enhanced

depth of focus, and

high-resolution 3CMOS mode.

|

6 Observation Methods and

Advanced Measurement Functions

Packed with advanced features,

this model features the universal

zoom head and adds a tilting

frame and motorized XY stage

with rotation (+ 90°).

|

DSX1000 Objective Lenses

Our lineup of 17 objective lenses, including super long working distance and high numerical aperture options, offers flexibility to obtain a wide range of images.

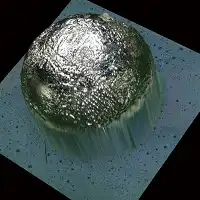

Super Long Working

Distance Objective Lens

Provides a long working distance

between the lens and sample.

|

High-Resolution, Long Working

Distance Objective Lens

Delivers both high resolution and

a long working distance.

|

High-Performance, High Numerical

Aperture Objective Lens

Delivers high performance at the nano scale.

|

Digital Microscope for Failure Analysis

Speed combined with guaranteed accuracy and repeatability make the DSX1000 digital microscope the right tool for fast failure analysis.

Macro to Micro Versatility

Preliminary Inspection and Micron-Level Analysis with One System

- See the whole picture: 23X to 8220X magnification range

- Minimize the chance of crashing into your sample

- See your sample from many angles

Supported models

Multiple Observations with a Single Click

Instant Switching Saves Time

- All observation methods are available at all magnifications

- Choose from 6 observation methods, and switch between them with a single click

Supported models

Be Confident in Your Results

Guaranteed* Measurement Accuracy and Precision

- You can be confident in your measurement results with guaranteed* measurement precision

- Reliable measurement with on-site calibration

Supported models

*To guarantee XY accuracy, calibration work must be undertaken by an Olympus service technician.

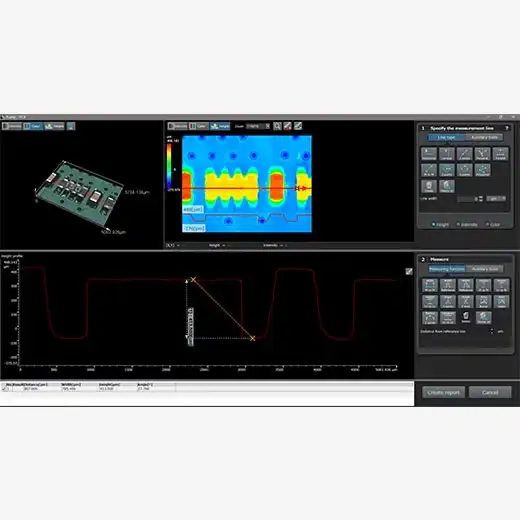

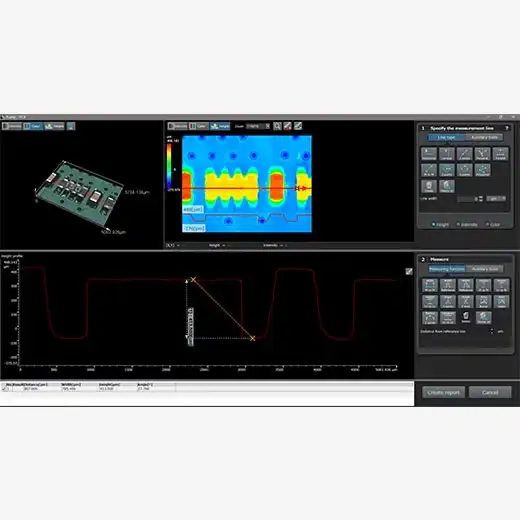

Advanced Measurements Are Fast and Easy to Obtain

Improved analysis functions make the DSX1000 digital microscope a powerful and versatile inspection tool

- Supports complex measurement, including profile , inter-surface step, surface roughness, and more.

- Faster analyses with advanced easy-to-use functions

Supported models

5 Advantages of the DSX1000 Series Digital Microscope Over Conventional Digital Microscopes

01

All-in-One System with a

Wide Magnification Range

|

With the DSX1000 digital microscope:

Complete your inspection using one

easy-to-use system

|

With a conventional digital microscope:

Two microscopes, a low-magnification and

a high-magnification model, are needed to complete an inspection

|

|

02

High-Resolution Image

at High Magnification

|

With the DSX1000 digital microscope:

High resolution and long working

distance in one objective

|

With a conventional digital microscope:

Resolution decreases as magnification increases

|

03

Long Working Distance Objectives

|

With the DSX1000 digital microscope:

Observe uneven samples without bumping into them

|

With a conventional digital microscope:

The objective can crash into the sample,

potentially damaging it

|

04

Multiple Observations with a Single Click

|

With the DSX1000 digital microscope:

All 6 observation methods are available at all magnifications

|

With a conventional digital microscope:

Only one or two observation methods are available,

limiting what can be seen in the sample

|

05

Guaranteed Accuracy and Precision

|

With the DSX1000 digital microscope:

Both accuracy and repeatability are guaranteed at all magnifications

|

With a conventional digital microscope:

The measurement precision is not guaran teed

|

Service and Support You Can Trust

From calibration to training, we offer a broad portfolio of services to help you maintain optimal device performance. Evident service contracts are:

- Straightforward—so you can focus on the core of your business

- Efficient—we can schedule preventative maintenance, including calibrations, on your behalf

- Cost-effective—providing you savings throughout the life of the contract

DSX1000 Application Notes

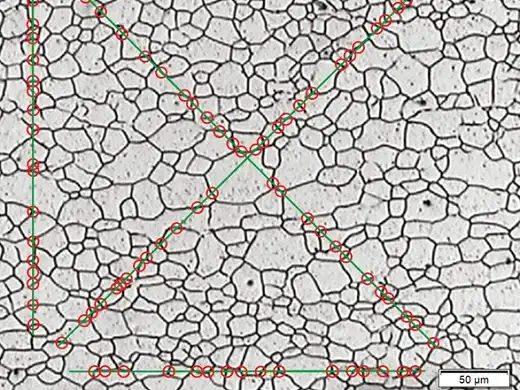

Improve the Speed and Efficiency of Your Inspection with Image Analysis Software

OLYMPUS Stream Software

The software offers fast, efficient inspection workflows for image acquisition, quantitative measurements and image analysis, reporting, and advanced materials science inspection tasks.

DSX1000 Applications

|

|

Perform Highly Accurate Thickness Measurements

of the Internal Layer of a Multilayer Ceramic Condenser

Multilayer ceramic condensers (MCLLs) have been attracting attention and it has found widespread

use in applications ranging from mobile terminals to automobiles. Moreover, it is expected that

large quantities of MCLLs will be incorporated into 5G devices. The DSX1000 it easy to

measure thickness of the Internal layer of MCLLs with high resolution.

|

|

|

|

Using a Digital Microscope for Precise Burr Measurement on Injection-Molded Products

Olympus' DSX1000 digital microscope makes it easier to obtain optimal images that facilitate the

quality control of burrs on injection-molded components. It comes equipped with various functions

that enable you to acquire images at the desired magnification, observation method, and

illumination angle, and an image-processing function.

|

|

|

|

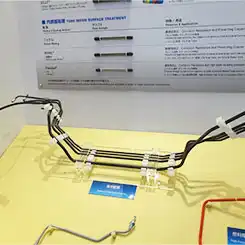

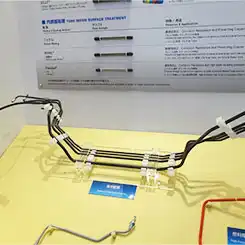

Measuring the Thickness of Automotive Pipe Coatings Using a Digital Microscope

In the quality control process, inspectors must assess coating thicknesses to make sure they meet

specifications and check for thickness variations. DSX1000 provides pattern matching and shading

correction algorithms that enable you to stitch images together.

|

|

|

|

Inspecting Burrs on Pistons Using a Digital Microscope

If there are burrs in the piston’s grooves, it can lead to serious engine issues. DSX1000

offers "Observe small burrs with clear images at low magnification" , "Instantly switch to a

higher magnification objective to analyze burrs" and " See the piston ring groove from different

angles with a tilting frame" and provide efficient workflow.

|

|

|

|

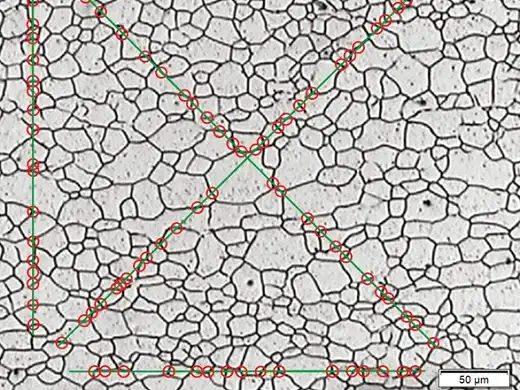

Observing the Metal Flow in Forged Products Using a Digital Microscope

There are many parts that are forged, such as gears, valves, and connecting rods used in

automobiles. DSX1000 can observe the metal flow that affects toughness using the auto-stitching

function.

|

|

|

|

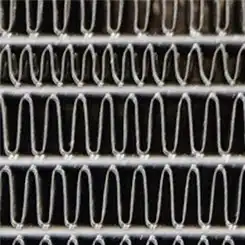

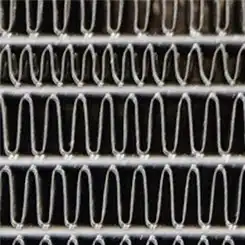

Inspecting the Brazed Joints of Radiator Fins Using a Digital Microscope

Radiator are important role in engine cooling and it is essential to confirm the brazing of pipes

and fins for quality control. DSX1000's multi-preview function makes it simple to view the sample

using multiple observation methods to find the right one and makes inspections more efficient.

|

|

|

|

Measuring a Connecting Rod’s Slit Width Using a Digital Microscope

Connecting rods are required to be strong enough to withstand tens of millions of revolutions

per minute, and the slit width is strictly controlled. With the DSX1000, the slit width that could not

be clearly observed with a conventional microscope can be observed with high accuracy.

|

|

|

|

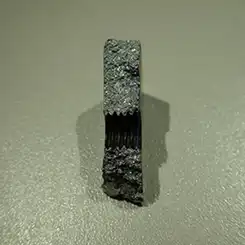

Inspecting a Brake Pad’s Surface using a Digital Microscope

A brake pad's surface impacts its performance, including braking force, heat stability, noise, and

heat generation. Digital microscopes are used to check that the compounds used to create the

brake pad are mixed properly.

|

|

|

|

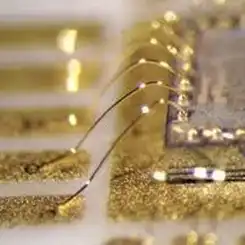

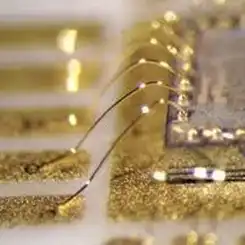

Inspecting Bonding Wires Using a Digital Microscope

Digital microscopes are effective tools for analyzing defects, such as wire breakage, wire pitch

deviation, bonding peeling, and migration that can occur during the bonding process.

|

|

|

|

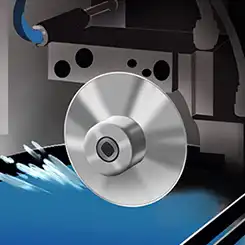

Detecting Damage on a Drill Bit Edge Using a Digital Microscope

Drill bits are widely used in industrial fields as a cutting tool. If the edge is damaged,

inaccuracies may arise during hole positioning, or the drill may break. Conventional digital

microscope is commonly used to perform drill inspection, but there are challenges.

The DSX1000 offers advantages of detecting damage on a drill bit edge.

|

|

|

|

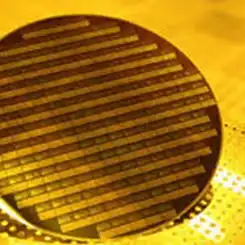

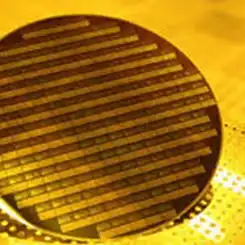

Detecting Manufacturing Defects on Semiconductor Wafers Using a Digital Microscope

Semiconductors are essential components in many electronic devices. Defects can be

introduced into the circuit during manufacturing process, and visual inspection using a

microscope is a preferred option to inspect defects. The DSX1000 simplifies semiconductor

visual inspection.

|

|

|

|

How a Digital Microscope’s Deep Focal Depth Enables the Complete Inspection of Connector Pins

Manufacturers use strict quality control measures to minimize failures of electrical

connector pins, and microscopes play an essential role. The DSX1000 microscope’s

objective lenses offer the depth of focus and resolution required to focus an entire connector

pin at the same time, greatly simplifying and speeding up the inspection process.

|

|

|

|

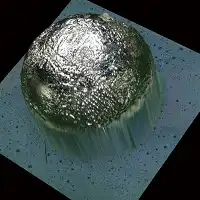

Analyzing Fractured Metal Surfaces with a Digital Microscope

Fractography has become increasingly important as infrastructure continues to age and quality

control issues cause problems. Optical or digital microscopes are essential fractography tools

that are used to capture high-quality images for analysis. See details of advantages which

DSX1000 can offer to analyze factured metal surfaces.

|

|

|

|

Measuring the Volume of Integrated Circuit Chipping After the Dicing Process Using a Digital Microscope

During the dicing process of integrated circuit (IC) manufacturing, amount of allowable

roughness of wafer surface is carefully controlled. Amount of roughness is checked with a digital

microscope, but the physical properties of IC chips can be challenging. The DSX1000 objective

lenses offer high resolution at low magnification to reduce shading and flare, enabling inspectors

to more easily see chipping during low-magnification observations.

|

|

|

|

Inspecting Glass Fiber Peeling in a Printed Wiring Board’s Glass Epoxy Substrate—

Clear Images Are Essential for Quality Control

Inspection of resin peeling defects is critical as these defects can cause a completed PWB to

have lower insulation and heat resistance, making them more susceptible to failure. PWBs are

challenging to inspect with a microscope. The DSX1000 digital microscope has advanced

telecentric optics and high-resolution objectives that offer an excellent depth of focus, which

enable you to observe an etched PWB to investigate the cause of a defect.

|

|

|

|

Acquiring Clear Images and Accurate Dimension Measurements of a

Laminated Ceramic Capacitor Using a Digital Microscope

Manufacturers measure the laminated ceramic capacitors’ dimensions and visually

inspect them to look for cracks in the ceramic. Microscopes or digital microscopes is used to

supplement the automated inspection system, but poses challenges. The DSX1000

offers multiple advantages to inspect capacitors.

|

|

|

|

Measuring the Circuit Shape of a Printed Wiring Board Using a Digital Microscope

During the manufacturing process of PWBs, a microscopic inspection is necessary to analyze

circuit shape precisely. There are multiple advantages of measuring circuit shape

with the DSX1000.

|

|

|

Automotive

|

Electronics

IC/Wafer

|

Metal Fabrication/Mold

|

Chemical/Materials,

Glass, and Ceramics

|

Other

|

DSX1000 Digital Microscope Specifications

|

|

DSX10-SZH |

DSX10-UZH |

| Optical System |

Optical system |

Telecentric optical system |

| Zoom ratio |

10X (motorized) |

| Zoom magnification method |

Motorized |

| Calibration |

Automatic |

| Lens attachment |

Quick-switch, coded lens attachments automatically update magnification and visual field information |

Maximum total magnification

(on a 27-inch monitor) |

8220X |

| Working distance (W.D.) |

66.1 mm – 0.35 mm |

| Accuracy and repeatability (X-Y plane) |

Accuracy*1 |

± 3% |

| Repeatability 3σn-1 |

2% |

| Repeatability (Z axis)*2 |

Repeatabilty σn-1 |

1 μm |

| Camera |

Image sensor |

1 / 1.2 inch, 2.35 million pixel color CMOS |

| Cooling |

Peltier cooling |

| Frame rate |

60 fps (maximum) |

| Standard |

1200 × 1200 (1: 1) / 1600 × 1200 (4: 3) |

| 3 CMOS mode |

Not available |

1200 × 1200 (1: 1) / 1600 × 1200 (4: 3) |

| 3 CMOS mode × pixel shift |

Not available |

3600 × 3600 (1: 1) / 4800 × 3600 (4: 3) |

| Illumination |

Color light source |

LED |

| Lifetime |

60,000 h (design value) |

| Observation |

BF (brightfield) |

Standard |

| OBQ (oblique) |

Standard |

| DF (darkfield) |

Standard

LED ring divided into four divisions |

| MIX (brightfield+darkfield) |

Standard

Simultaneous observation of BF + DF |

| PO (polarization) |

Standard |

| DIC (differential interference) |

Not available |

Standard |

| Contrast up |

Standard |

| Depth of focus up function |

Not available |

Standard |

| Transmitted lighting |

Standard*3 |

| Focus |

Focusing |

Motorized |

| Stroke |

101 mm (motorized) |

*1 Calibration by Olympus or dealer service technician necessary. To guarantee the accuracy of XY, calibration with DSX-CALS-HR (calibration sample) is required. To issue certificates, calibration work must be undertaken by an Olympus’ calibration service technician.

*2 When using a 20X or higher objective.

*3 The optional DSX10-ILT is required.

| Objective |

DSX10-SXLOB |

DSX10-XLOB |

UIS2 |

| Objective lens |

Maximum sample height |

50 mm |

115 mm |

145 mm |

Maximum sample height

(free angle observation) |

50 mm |

| Parfocal distance |

140 mm |

75 mm |

45 mm |

| Lens attachment |

Integrated with lens |

Available |

Total magnification

(on a 27-inch monitor) |

23 – 1644X |

49 – 6570X |

26*4 – 8220X |

| Actual F.O.V. (μm) |

19,200 µm – 270 µm |

9,100 µm – 70 µm |

17,100 µm – 50 µm |

| Adaptor |

Diffusion adaptor (optional) |

Available |

Not Available |

| Eliminate reflection adaptor (optional) |

Available |

Not Available |

| Lens attachment |

Number of objectives that can be attached |

Up to 1 piece

(attachment is integrated with lens) |

Up to 2 pieces |

| Objective lens case |

Three lens attachments can be stored |

*4 Total (maximum) magnification when using MPLFLN1.25X

| Stage |

DSX10-RMTS |

DSX10-MTS |

U-SIC4R2 |

| XY stage: motorized / manual |

Motorized (with rotation function) |

Motorized |

Manual |

| XY stroke |

Stroke priority mode: 100 mm × 100 mm

Rotation priority mode: 50 mm × 50 mm |

100 mm × 100 mm |

100 mm × 105 mm |

| Rotation angle |

Stroke priority mode : ±20°

Rotation priority mode : ±90° |

Not available |

| Display rotation angle |

GUI |

Not available |

| Load-resistance |

5 kg (11 lb) |

1 kg (2.2 lb) |

| Frame |

DSX-UF |

DSX-TF |

| Z-axis stroke |

50 mm (manual) |

| Tilt observation |

Not available |

±90° |

| Tilt angle display |

Not available |

GUI |

| Tilt angle method |

Not available |

Manual, fix / release handle |

| Measurement |

Plane measurement |

| Profile measurement |

| Step measurement |

| Step height measurement |

| Area/volume measurement |

| Line roughness analysis |

| Surface roughness analysis |

| Auto edge measurement |

| Particle analysis |

| Difference measurement |

| Sphere/cylinder surface angle analysis |

| Multi-data analysis* |

*Requires Experimental total assist application software (optional)

| Display |

27-inch flat panel display |

| Resolution |

1920 (H) × 1080 (V) |

| System total |

Upright frame system |

Tilt frame system |

| Weight (frame, head, motorized stage, display, and console) |

43.7 kg (96.3 lb) |

46.7 kg (103 lb) |

| Power consumption |

100 – 120 V / 220 – 240 V, 1.1 / 0 .54 A, 50 / 60 Hz |

DSX1000_Brochure_CN

DSX1000_Brochure_CN

DSX1000_Brochure_EN

DSX1000_Brochure_EN

Microsystem

Microsystem Endoscopysystem

Endoscopysystem Energysystem

Energysystem EndoscopyConsumables

EndoscopyConsumables +86-21-54286005

+86-21-54286005

Room 602, Building 1, No. 111 Luxiang Road (Greenland Park Plaza), Baoshan District, Shanghai, China

Room 602, Building 1, No. 111 Luxiang Road (Greenland Park Plaza), Baoshan District, Shanghai, China  English

English

中文

中文