Evident LEXT OLS5500 3D Optical Profilometer

Evident LEXT OLS5500 3D Optical Profilometer

Phone:+86-21-54286005

Microsystem

Microsystem

Endoscopysystem

Endoscopysystem

Energysystem

Energysystem

+86-21-54286005

+86-21-54286005

info@tenmed.net

info@tenmed.net

Room 602, Building 1, No. 111 Luxiang Road (Greenland Park Plaza), Baoshan District, Shanghai, China

Room 602, Building 1, No. 111 Luxiang Road (Greenland Park Plaza), Baoshan District, Shanghai, China

Evident LEXT OLS5500 3D Optical Profilometer

Phone:+86-21-54286005

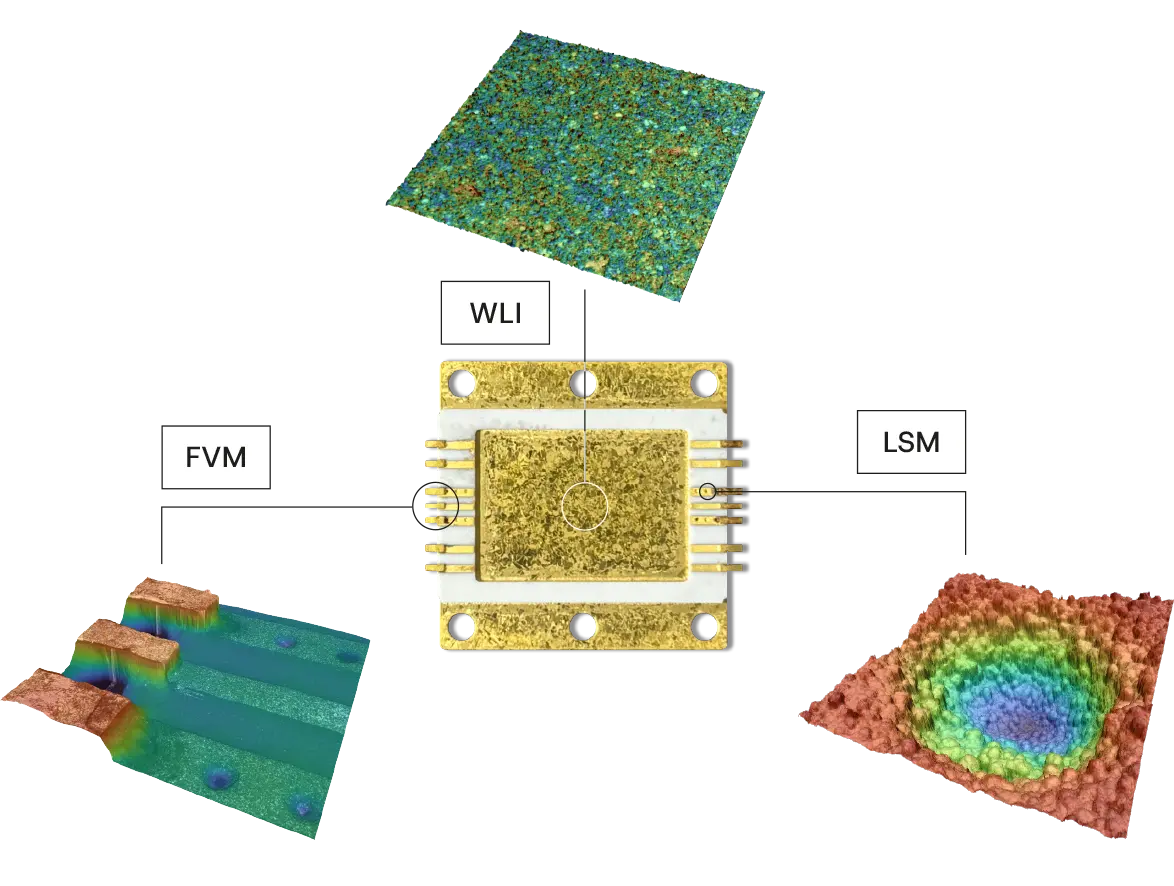

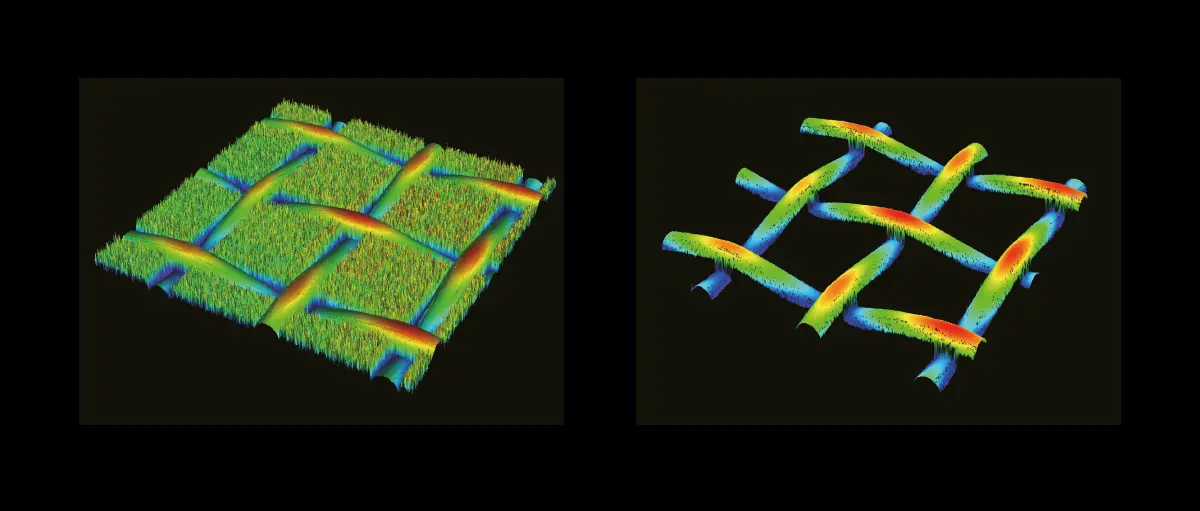

The LEXT™ OLS5500 hybrid 3D optical profilometer unites laser scanning microscopy (LSM), white light interferometry (WLI), and focus variation microscopy (FVM) in one powerful platform. Designed for R&D, QA, and QC teams, it delivers precise surface detail, traceable accuracy for confident measurements, and an intuitive user experience to streamline workflows. Trusted data—powered by precision optics, verifiable calibration, and smart automation—helps labs move seamlessly from first discovery to final decision.

Each method complements the others—delivering the right imaging mode for every surface. Generate comprehensive, true-to-form surface data from nanometers to millimeters and flat to steep slopes, all in a single system.

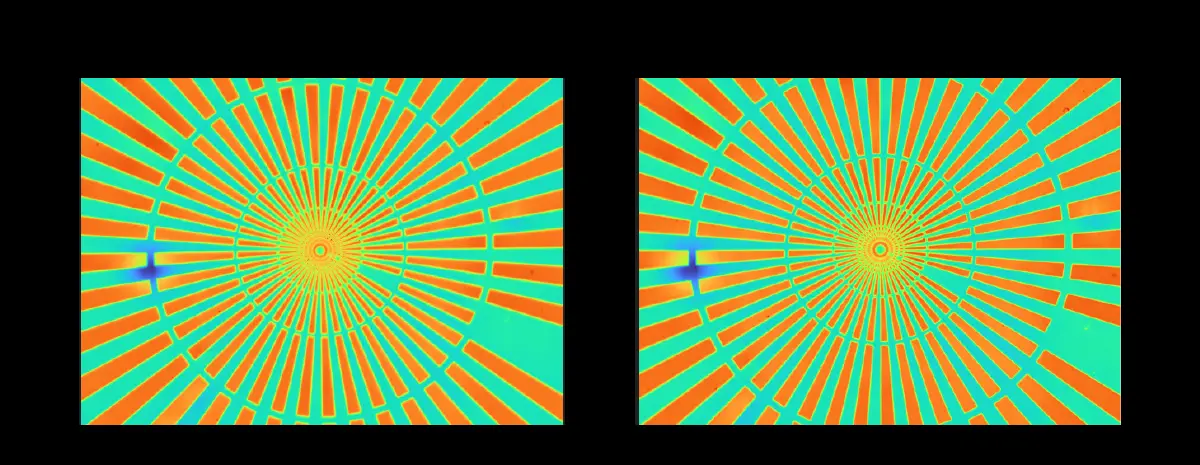

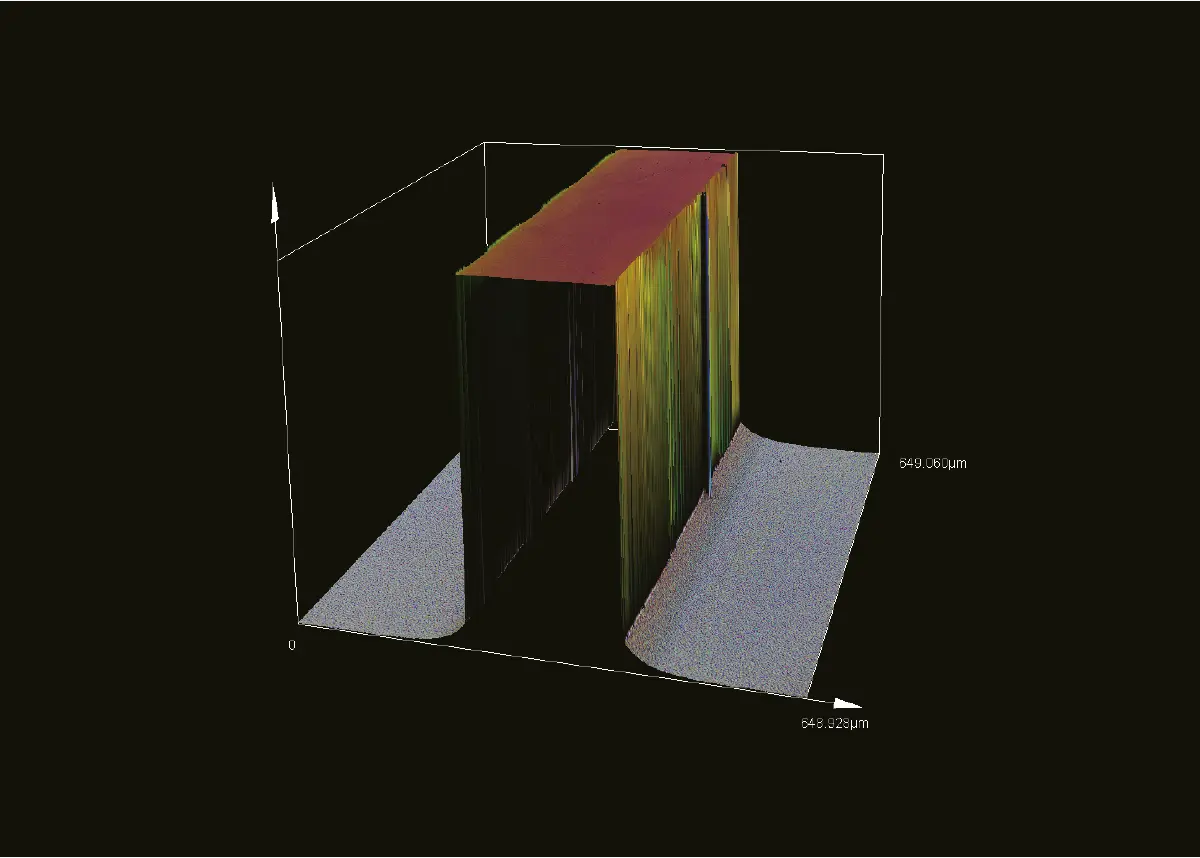

RF package imaged using three surface metrology techniques.

The OLS5500 enables you to identify subtle features and surface variations with unparalleled clarity—use LSM, WLI, and FVM to detect defects, confirm designs, and make confident decisions.

Whether you're working with highly sloped samples, reflective surfaces, or complex geometries, in-house engineered objective lenses maintain clarity and shape fidelity across the full field of view.

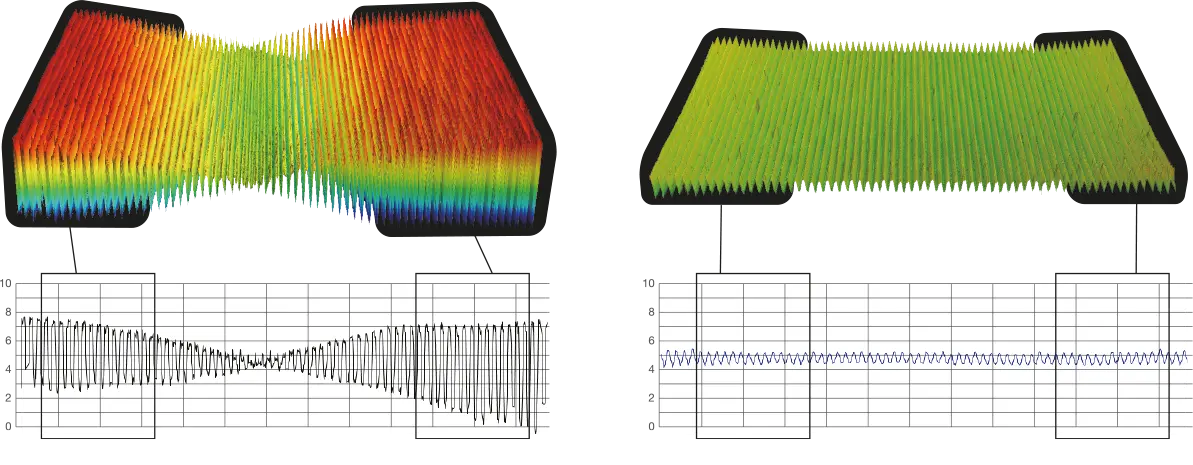

Left: With conventional lenses, distortion increases at the periphery and affects measurement accuracy. Right: With LEXT lenses, the periphery is reproduced free of distortion for accurate measurements.

Dedicated LEXT objectives accurately measure peripheral areas, overcoming the measurement challenges of conventional lenses.

LEXT objective lenses from left to right: long working distance (20X, 50X, 100X), high performance (20X, 50X, 100X), and low magnification (10X).

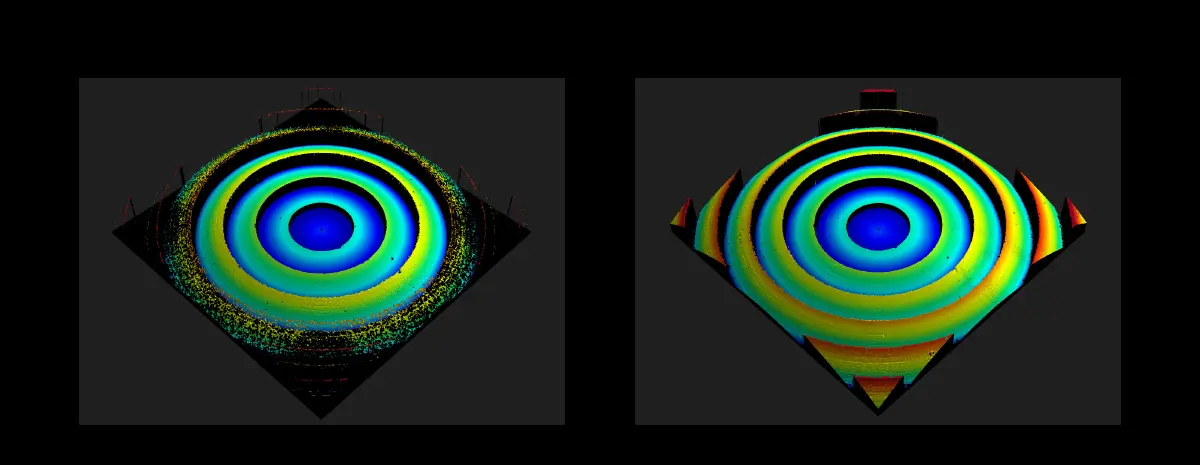

High NA WLI objectives (up to 0.8 NA) produce sharp interference fringes and exceptional phase stability, even on steep or textured surfaces.

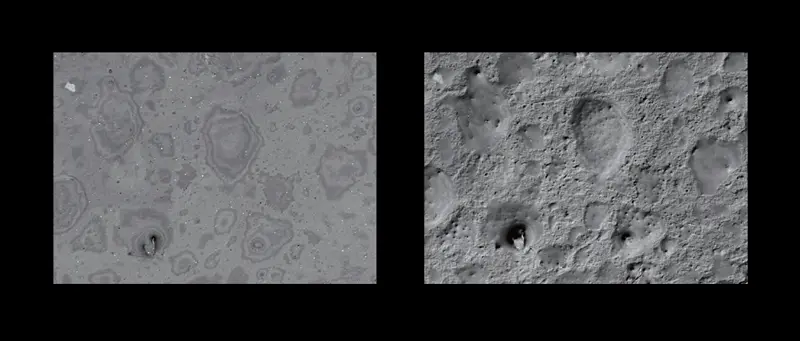

Comparison images of a Fresnel lens sample taken with a conventional WLI 20X objective (left, NA 0.4) and Evident’s 20X WLI objective (right, NA 0.6).

Comparison images of a Fresnel lens sample taken with a conventional WLI 50X objective (left, NA 0.55) and Evident’s 50X WLI objective (right, NA 0.8).

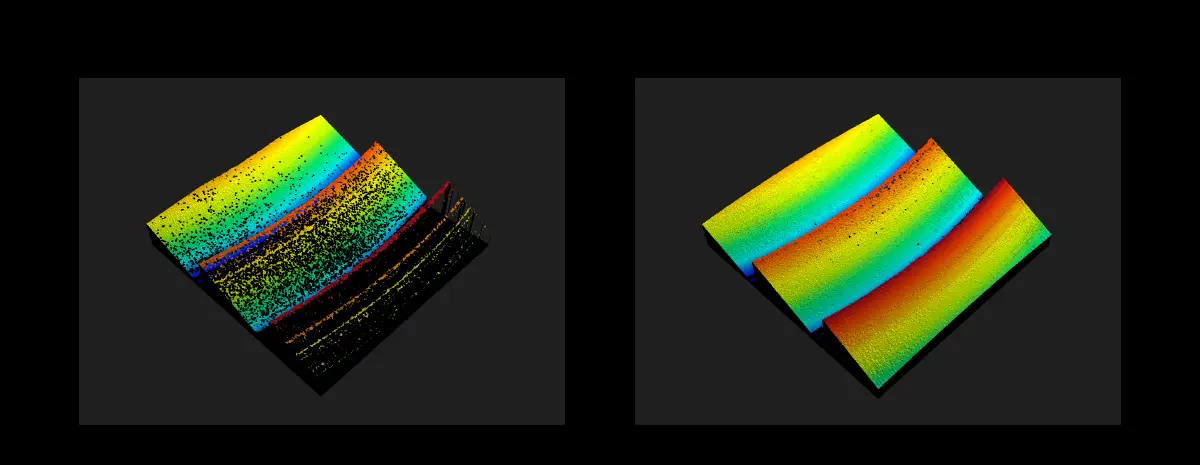

Comparison images of a calibration sample taken with a conventional WLI 50X objective (left, NA 0.55) and Evident‘s 50X WLI objective (right, NA 0.8).

Improve validation speed by revealing critical features that are invisible to conventional systems. From fine structures and subtle topography to transparent surfaces and low-contrast features, the OLS5500 provides multiple contrast-enhancing options to expose hidden or subtle details.

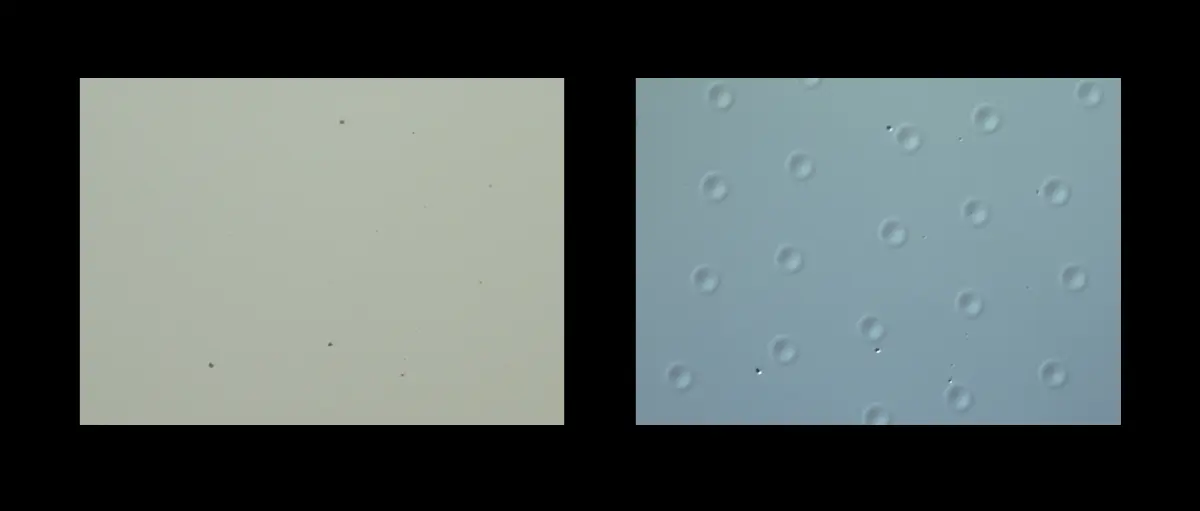

Comparison images of a polymer film. Left: laser image without DIC. Right: laser image with DIC.

Comparison images of a hard disk landing zone. Left: color image without DIC. Right: color image with DIC.

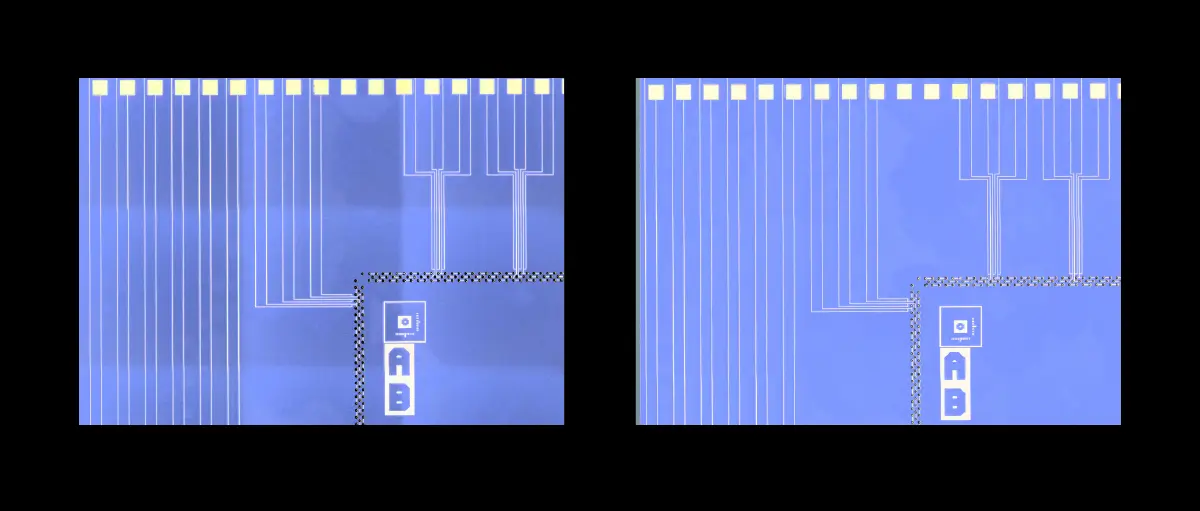

Inspect larger regions—without losing detail or image integrity. Intelligent Shading Correction minimizes artifacts and balances illumination across stitched images, ensuring seamless results even on low-contrast or uneven surfaces. This edge-to-edge clarity supports consistent analyses.

Comparison stitched images of a wafer. Left: without Intelligent Shading Correction. Right: with Intelligent Shading Correction.

Fewer retests, reworks, and rejections—thanks to trusted measurements in LSM, WLI, and FVM that you can verify and prove.

Obtain consistent, high-precision measurements across applications—the OLS5500 is the world’s first 3D optical profilometer that ensures guaranteed accuracy and repeatability* for both LSM and WLI measurements.

On-site calibration by Evident technicians ensures precise, repeatable measurements with time-stamped records that support alignment with international metrology standards.

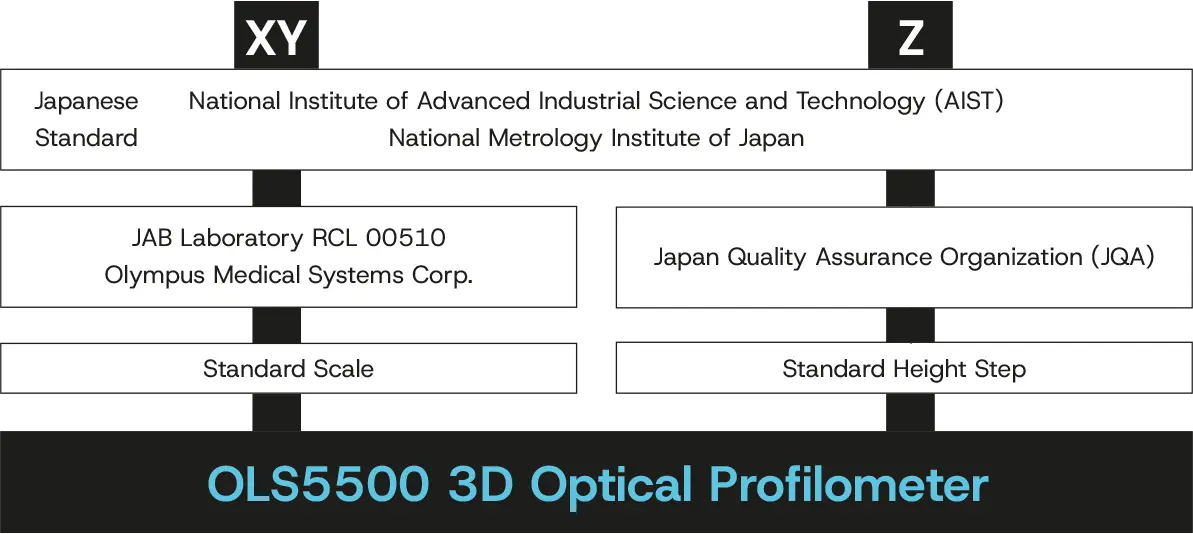

Every value you measure is validated through our traceable calibration process, giving you results you can defend across audits, reports, and production reviews.

*Based on Evident’s internal research as of October 2025. The guaranteed accuracy and repeatability apply only if the device has been calibrated according to the manufacturer‘s specifications and is in defect free condition. Calibration must be performed by an Evident technician or an Evident-authorized specialist.

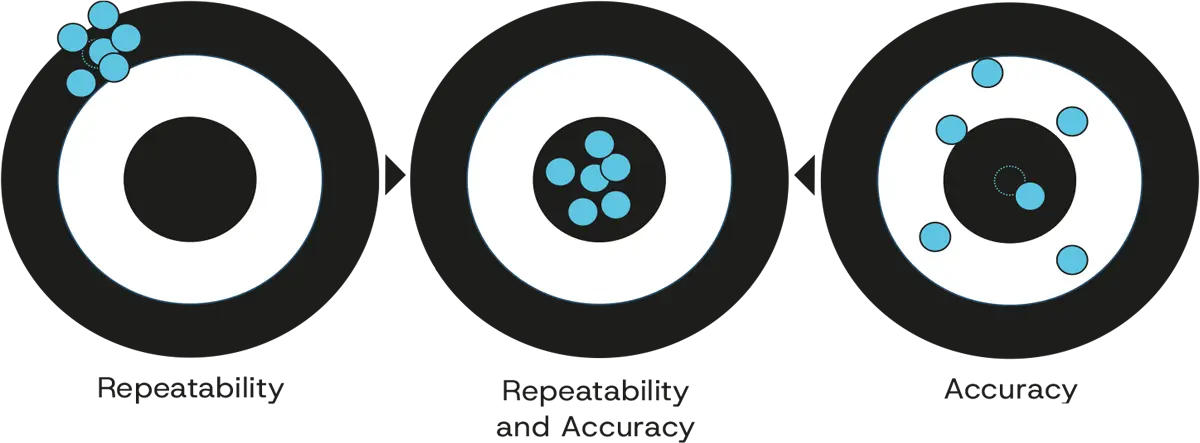

Illustration showing the difference between accuracy and repeatability.

Example for the AIST standard

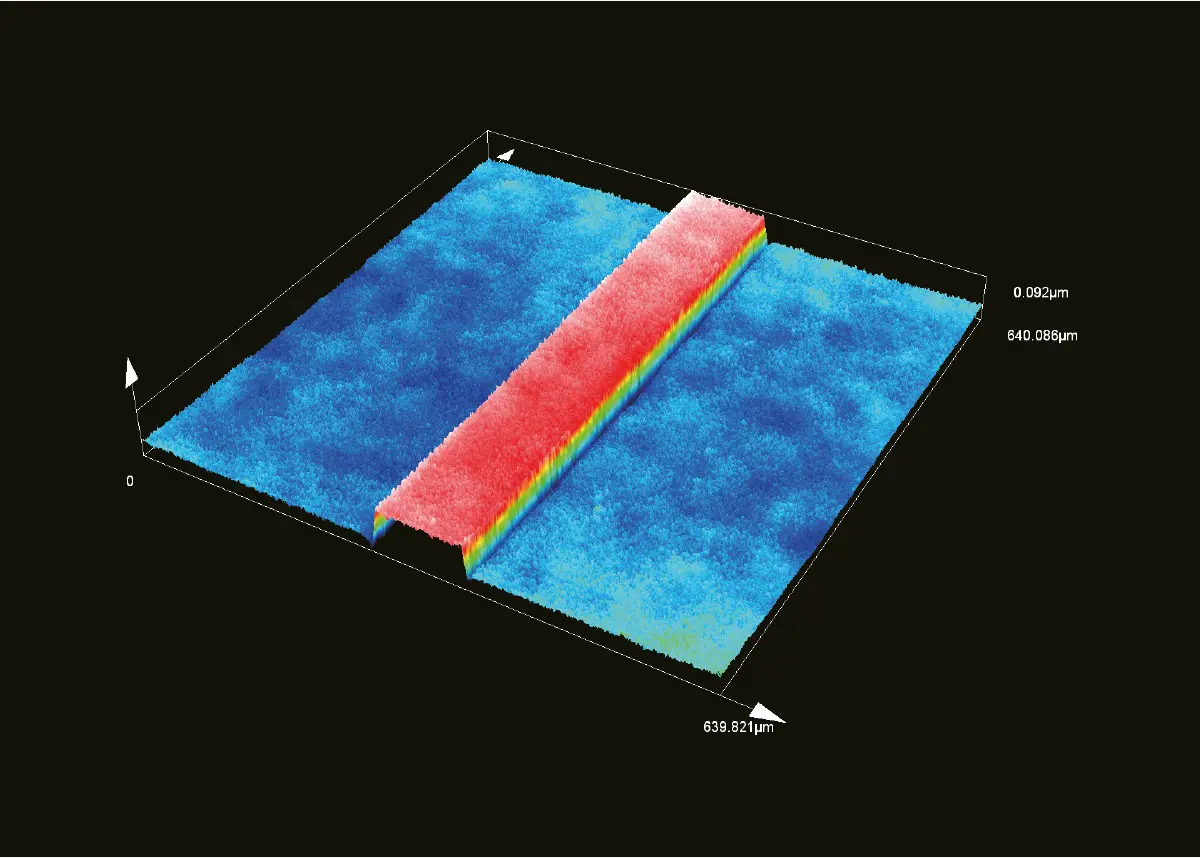

Trust your height measurements—even at the nanometer scale. The OLS5500 guarantees measurement noise levels* in accordance with ISO 25178-700:2022:

This ensures high-resolution detection of even the most subtle topographic changes, from thin films to micro-patterned surfaces.

*You will receive a Measurement Noise Guarantee Certificate. This is a representative value measured under conditions specified by Evident and may differ from the guaranteed value.

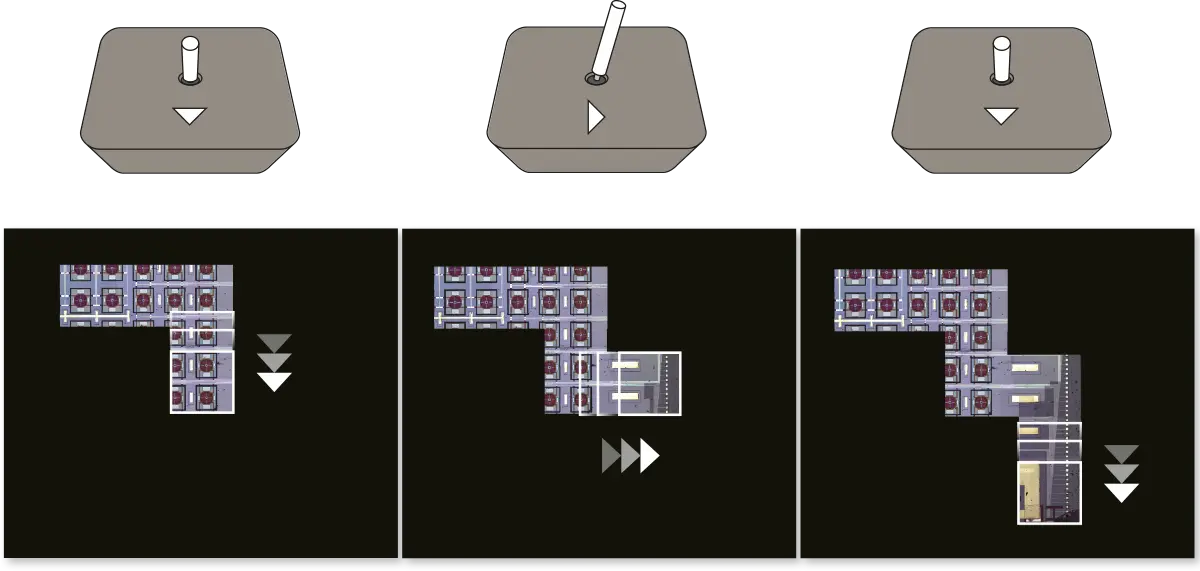

The OLS5500 incorporates a length-measuring module in its motorized stage, guaranteeing* the accuracy of stitched image data. While conventional systems rely only on pattern matching, the OLS5500 combines that with positional feedback, providing highly reliable stitched data for both LSM and WLI.

*The guaranteed accuracy for stitched images applies only to the 100 mm motorized stage. (OLS5500-SAF is available for both LSM and WLI, and OLS5500-EAF is available only for LSM).

Length measurement module

When it comes to protecting your investment and the integrity of your research, your needs come first. We stand behind our products with a commitment to prompt service and technical support to help you achieve your goals.

Maintain compliance and system uptime with our on-site calibration, global service network, and remote support—backed by 100+ years of expertise in microscopy.

The OLS5500's smart automation and workflow tools are designed to make surface analysis easier and faster for users of all levels. Obtain consistent, first-time-right results in LSM, WLI, and FVM to maximize inspection efficiency and throughput.

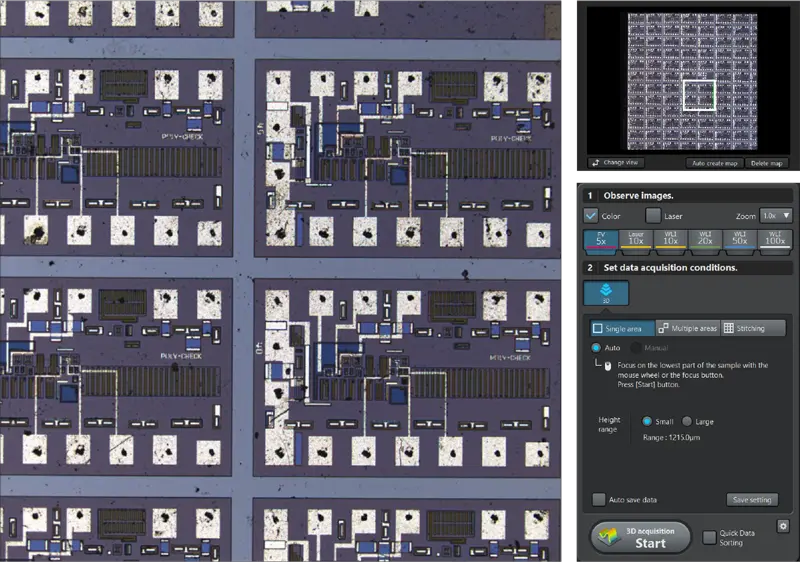

The OLS5500 automatically generates a macro map as the stage moves, keeping every area tracked and documented for effortless navigation. With continuous autofocus, focus remains sharp throughout movement—no manual refocusing, no interruptions.

The OLS5500 automates key measurement processes so your focus stays on analysis, not adjustment.

Acquire data quickly and easily with Smart Scan II for LSM. Place the sample on the stage, press the start button, and the system does the rest.

PEAK algorithm provides highly accurate data from low to high magnifications and reduces the data acquisition time. When measuring the shape of steps on a sample, the data acquisition time can be reduced by skipping the unnecessary scanning range in the Z-direction.

VLSI standard 83 nm height sample (MPLFLN10LEXT).

Resist pattern on a silicon surface. Courtesy of the Nanotechnology Hub at Kyoto University.

With Tilt Adjustment Assistance, tilt correction becomes simple. With one click, the software indicates the exact amount of adjustment needed to level the sample surface. Simply follow this guidance to operate the stage.

Smart Judge automatically detects only reliable data, delivering accurate measurements without losing fine height irregularity data.

Left: Smart Judge off: Right: Smart Judge on.

The OLS5500's intuitive software interface supports fast, reliable, and repeatable measurements at scale for users of all levels. Guided workflows simplify setup and ensure consistent operation across teams.

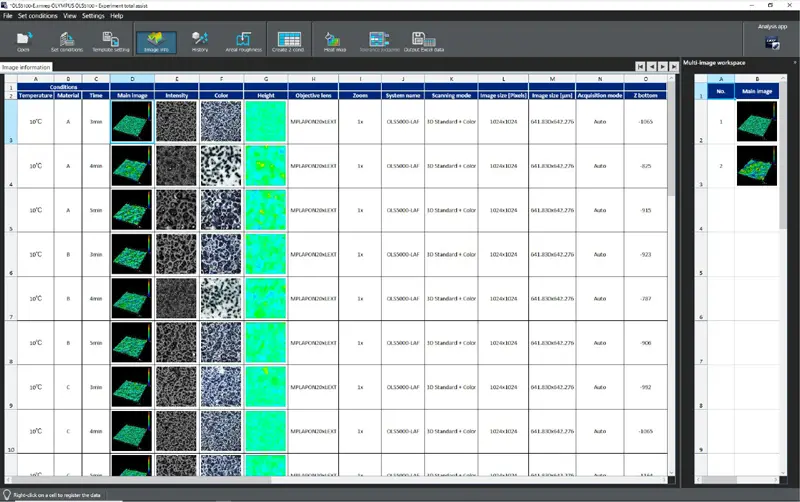

Automate inspections with macros—create, edit, and run procedures for reliable results. Pair with the Smart Experiment Manager to make pass/fail decisions in a single click. Save reports as templates to streamline repeated measurements and ensure consistent results across analyses and users.

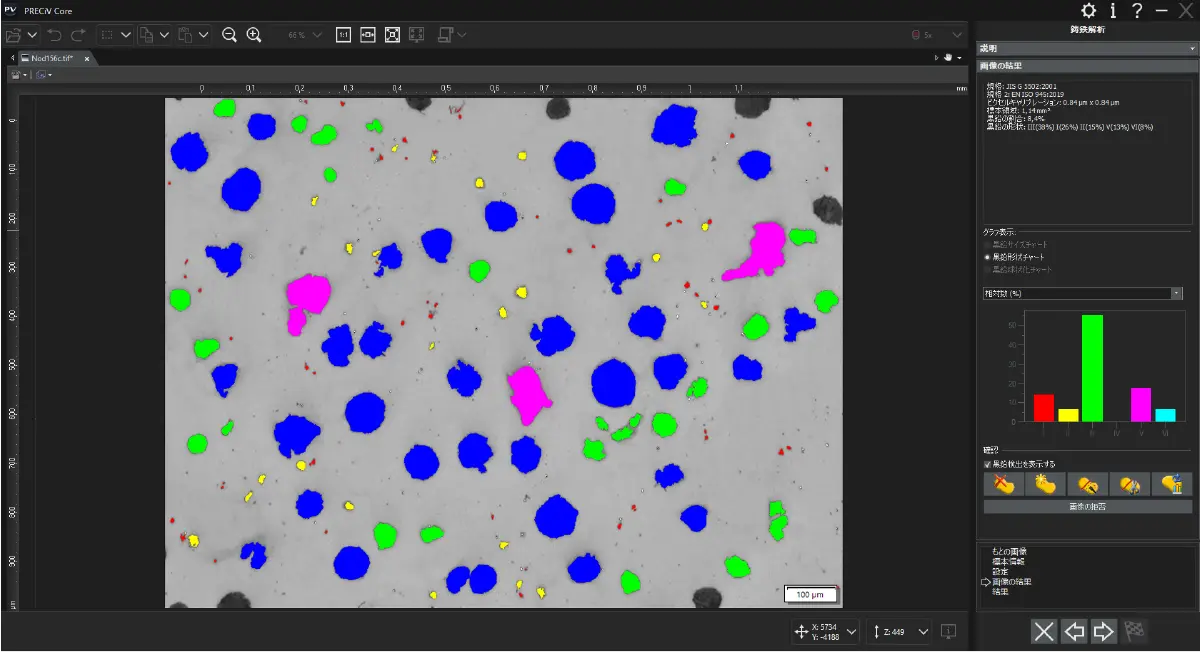

PRECiV™ software integration for routine metallography, AI-enhanced workflows, and advanced 2D analysis supports specialized applications and high-throughput production environments.

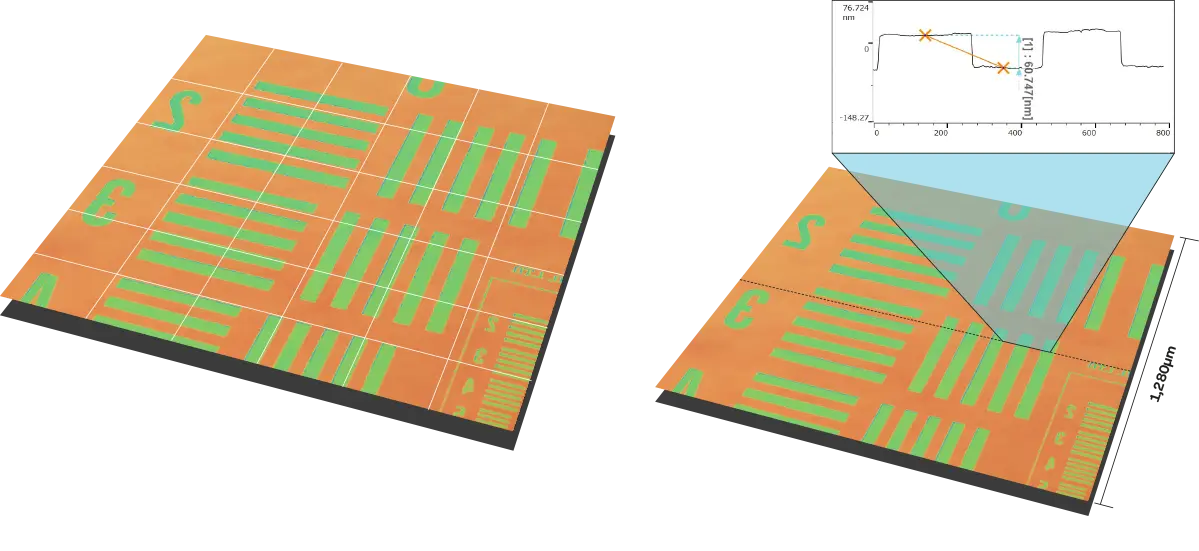

The OLS5500 delivers both speed and precision. Its advanced white light interferometry (WLI) mode accelerates surface measurements by up to 40 times compared to conventional LSM—without losing accuracy or traceability.

Sample: 60 nm step height, measurement area: 1,280 µm.

LSM: Data acquisition time: 630 s; 6×6 stitched image acquired with an LSM 50X objective (NA 0.95).

WLI: Data acquisition time: 15 s; single image acquired with a WLI 10X objective (NA 0.3).

Save time imaging large or complex samples. The OLS5500’s high NA Mirau WLI objectives expand the measurable field of view while preserving vertical precision.

Fewer images per area mean fewer image stitching steps, improving efficiency while maintaining traceable, high-fidelity data.